Description

Introduction

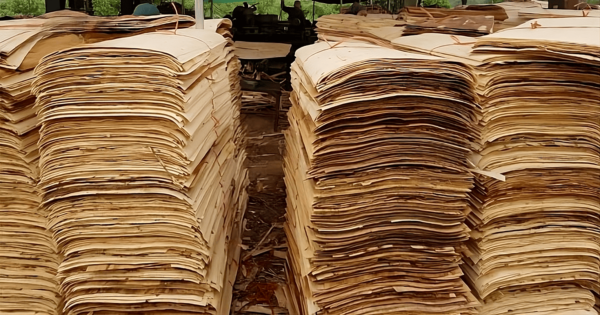

Core veneer is an essential component in the manufacturing of plywood and engineered wood products. It refers to the inner layers of veneer used to create a strong, lightweight, and stable core in plywood panels. With its unique properties and applications, core veneer plays a crucial role in various industries, from construction to furniture making. This article explores the characteristics, production process, applications, and advantages of core veneer, highlighting its significance in the modern wood industry.

What is Core Veneer?

Core veneer consists of thin sheets of wood sliced from logs, used as the central layers in plywood. These veneers are bonded together, usually in a cross-laminated pattern, to create a strong and stable core. The outer layers of veneer, often referred to as face veneer, are then glued on top to provide a finished surface. Core veneer is typically made from softer wood species, which are more readily available and economical, contributing to the overall strength and stability of the plywood.

Types of Core Veneer

- Softwood Core Veneer: Commonly used in standard plywood production, softwood core veneers are derived from species such as pine, fir, and spruce. They offer excellent strength-to-weight ratios and are cost-effective.

- Hardwood Core Veneer: Hardwood core veneers are less common but may be used in specialty plywood applications where aesthetics and additional strength are required. They are made from species such as oak, maple, and birch.

- Composite Core Veneer: This type combines different species or materials to enhance the properties of the core. For instance, a composite core may include both softwood and hardwood veneers to achieve a balance between strength, weight, and cost.

- Fire-Retardant Core Veneer: Treated with fire-retardant chemicals, this type of core veneer is designed for applications requiring increased fire resistance, making it suitable for commercial and industrial settings.

Production Process of Core Veneer

The production of core veneer involves several key steps that ensure quality and consistency in the final product:

- Log Selection: Quality core veneer starts with selecting the right logs. Manufacturers typically choose logs based on species, size, and quality. Softwood logs are often preferred due to their availability and cost-effectiveness.

- Veneer Cutting: The selected logs are debarked, and the wood is sliced or peeled into thin sheets of veneer. This process can be done using various methods, including rotary peeling, flat slicing, or quarter slicing, depending on the desired thickness and grain pattern.

- Drying: The sliced veneers are then dried to reduce their moisture content. Proper drying is crucial to prevent warping and ensure good adhesion during the lamination process.

- Lamination: Dried core veneers are stacked and bonded together using strong adhesives. The cross-laminated construction enhances the strength and stability of the core veneer, making it suitable for various applications. The assembled layers are then pressed under high pressure to cure the adhesive.

- Trimming and Finishing: Once the laminated core veneer is cured, it is trimmed to the desired size. Additional finishing processes, such as sanding and sealing, may be applied to achieve a smooth surface suitable for further manufacturing.

- Quality Control: Throughout the production process, quality control measures are implemented to ensure that the core veneer meets industry standards. This includes testing for strength, moisture content, and surface defects.

Applications of Core Veneer

Core veneer is utilized in a variety of applications across different industries, including:

- Plywood Manufacturing: The primary use of core veneer is in the production of plywood panels. It serves as the structural core that provides strength and stability while allowing for lightweight construction.

- Furniture Production: Core veneer is commonly used in furniture making, particularly for creating lightweight yet sturdy furniture pieces. Its aesthetic versatility allows for various finishes and designs.

- Cabinetry: In cabinetry, core veneer is used for creating cabinet doors, shelves, and other components. Its stability ensures that cabinets maintain their shape and integrity over time.

- Interior Design: Architects and designers use core veneer in interior applications, such as wall panels, ceilings, and decorative elements, thanks to its visual appeal and durability.

- Construction: Core veneer is also used in construction for non-structural applications, such as partitions and decorative wall panels, where lightweight and stable materials are needed.

- Transport and Packaging: Core veneer is employed in the manufacturing of pallets, crates, and shipping containers, providing a strong and lightweight solution for transportation needs.

Benefits of Core Veneer

Core veneer offers numerous advantages that make it a preferred choice in various applications:

- Strength and Stability: The cross-laminated construction of core veneer enhances its strength and stability, making it less prone to warping and bending compared to solid wood.

- Cost-Effectiveness: Core veneer is typically more affordable than solid wood, allowing manufacturers and builders to save on material costs without compromising quality.

- Lightweight: Core veneer provides a lightweight alternative to solid wood, making it easier to handle and transport while still offering excellent structural performance.

- Sustainability: When sourced from sustainably managed forests, core veneer is considered an environmentally friendly option. The efficient use of wood fibers also contributes to reduced waste.

- Versatility: Core veneer can be used in a wide range of applications, from structural elements to decorative features, making it a versatile choice for builders and designers.

- Ease of Workability: Core veneer can be easily cut, shaped, and finished, allowing for creativity in design and construction.

Challenges and Considerations

While core veneer has many benefits, there are also challenges to consider:

- Quality Variation: The quality of core veneer can vary significantly based on the manufacturer and production methods. It is essential to choose core veneer from reputable sources to ensure consistency.

- Environmental Impact: The production of core veneer may involve the use of adhesives that contain formaldehyde or other chemicals. Opting for low-emission or eco-friendly adhesives can help mitigate this issue.

- Surface Finishing: While core veneer can be finished to achieve a beautiful appearance, it may require more care in finishing compared to solid wood, especially to achieve a flawless surface.

Conclusion

Core veneer is an essential component in the manufacturing of plywood and engineered wood products. Its unique properties, versatility, and cost-effectiveness make it a preferred choice for a wide range of applications in construction, furniture making, and interior design. As the demand for sustainable building materials continues to grow, core veneer stands out as an environmentally friendly option when sourced responsibly.

With advancements in technology and production methods, the future of core veneer looks promising. Whether you are a builder, designer, or manufacturer, understanding the benefits and applications of core veneer can help you make informed decisions for your projects.

Investing in high-quality core veneer not only enhances the strength and aesthetics of your work but also contributes to a more sustainable future for the wood industry. Embrace the versatility of core veneer and explore the endless possibilities it offers in your next project.